| Category |

Items |

Five -Axis |

| 200MA-5 |

200MB-5 |

210MA-H5 |

210MB-H5 |

220MA-5 |

220MB-5 |

| Product Specification |

Max. PLC Controlled Paths |

4 |

4 |

4 |

| Max. PLC Controlled Paths |

3 |

3 |

3 |

| Standard Axis |

8 |

12 |

8 |

12 |

8 |

12 |

| Max. Axis (Optional) |

9 |

16 |

9 |

16 |

9 |

16 |

| Max. Spindle |

6 |

6 |

6 |

| Max. Simultaneous Axis Control |

5 |

5 |

5 |

5 |

| Min. Control (mm) |

0,0001 |

0,0001 |

0,0001 |

| Max. number of program coordinate |

100 |

100 |

100 |

| Max. Number of Table Tools |

96 |

96 |

96 |

| Multi-Channel Function Group |

4 |

4 |

4 |

| Look-Ahead Blocks no. |

2000 |

2000 |

2000 |

| Block Processing timT |

4000 |

4000 |

4000 |

| Hardware Specifications |

Storage DISKA (MB) |

256 |

4096 |

4096 |

| Standard I/O |

32/32 |

32/32 |

32/32 |

| Optional I/O |

96/96 |

96/96 |

128/128 |

| DA |

1 |

2 |

─ |

| Monitor (Inch) |

10.4/15 |

10,4 |

10.4/15 |

| CF Card |

1 |

─ |

─ |

| CF Card |

2 |

2 |

2 |

| USB |

2 |

─ |

─ |

| RJ-45 |

2 |

1 |

2 |

| VGA Output |

1 |

1*** |

─ |

| PS/2 |

1 |

─ |

─ |

| RS-232 |

1 |

─ |

─ |

| RS-422 |

1 |

─ |

─ |

| RS-485 |

1 |

1 |

1 |

| USB |

2 |

─ |

2 |

| SRI |

─ |

1 |

1 |

| Servo Control |

Pulse Train (A/B Phase) |

─ |

─ |

─ |

| Pulse Train (CW/CCW) |

─ |

─ |

─ |

| Mechatrolink II |

O |

O |

─ |

| Mechatrolink III |

─ |

O |

O |

| EtherCAT |

─ |

O |

O |

| RTEX |

─ |

O |

O |

| Compensation |

Backlash Compensation |

O |

O |

O |

| Pitch Error Compensation |

O |

O |

O |

| Angular Error Compensation |

O |

O |

O |

| Temperature Error Compensation |

O |

O |

O |

| 2 Dimension Error Compensation |

O |

O |

O |

| Operation |

MPG Simulation |

O |

O |

O |

| Dry Run |

O |

O |

O |

| Optional Stop |

O |

O |

O |

| Single Block |

O |

O |

O |

| Virtual MPG |

O |

O |

O |

| Restart at Feedhold |

O |

O |

O |

| Restart at Break Point |

O |

O |

O |

| Tool Return |

O |

O |

O |

| Fixture Offsets |

O |

O |

O |

| MPG Offsets |

O |

O |

O |

| Programming |

Optional Skip |

O |

O |

O |

| B-Stop |

O |

O |

O |

| Absolute Zero Point Coordinate (G92/G92.1) |

O |

O |

O |

| Interrupt Macro (M96/M97) |

O |

O |

O |

| M198 call Subroutines |

O |

O |

O |

| Expandable G Code |

O |

O |

O |

| HSHP |

Constant Jerk Control |

O |

O |

O |

| Multiblocks S-curve motion plan |

O |

O |

O |

| Auto declaration in Corner |

O |

O |

O |

| Speed Limit for Round Radius |

O |

O |

O |

| Multiple Sets of HSHP Parameters |

O |

O |

O |

| Quick Parameter Setup |

O |

O |

O |

| SPA Feature |

O |

O |

O |

| Virtual Radius Funciton (for Rotary Axis) |

O |

O |

O |

| HSHP Control Mode I (G05.1 Q1) |

O |

O |

O |

| HSHP Control Mode II (G05P10000) |

Δ |

O |

O |

| NURBS Interpolation Ability |

Δ |

O |

O |

Tool

Management |

Auto Tool Setting |

O |

O |

O |

| Auto Tool Management |

O |

O |

O |

| Tool Life Management |

O |

O |

O |

| Accessibility |

Machine Lock (R bit) |

O |

O |

O |

| Software Limit |

O |

O |

O |

| Spindle Speed Arrival Check |

O |

O |

O |

| Axis Synchronize Feature |

O |

O |

O |

| Dynamic Axis Synchronize Feature |

O |

O |

O |

| Dynamic Axis Synchronize Feature |

O |

O |

O |

| Rapid Retraction for Rigid Tapping |

O |

O |

O |

| Virtual Axis Feature |

O |

O |

O |

| Axis Change Feature |

O |

O |

O |

| Axial Torque Limit |

O |

O |

O |

| Serial Bus Setting Feature(CNC Axis) |

O |

O |

O |

| Driver Information Display(CNC Axis) |

O |

O |

O |

| Spindle Application Feature(CNC Axis) |

O |

O |

O |

| Serial Bus PLC Axis |

O |

O |

O |

| ROT Element |

O |

O |

O |

| Dipole Front and Back System |

O |

O |

O |

| Data Backup Recovery |

O |

O |

O |

| Customized Opening Screen |

O |

O |

O |

| My Favorites (Only Eight key system supports) |

O

─ |

O |

O |

| Project Protection Feature |

O |

O |

O |

| Limit Access Manager |

O |

O |

O |

| Remote AP Monitor |

O |

O |

O |

| Edit |

Background Edit |

O |

O |

O |

| Edit Protection |

O |

O |

O |

| Immediate Grammar Check |

O |

O |

O |

| PLC |

PLC Diagnosis Feature(FORCE I Point) |

O |

O |

O |

| Data Transfer |

NETWORK |

O |

O |

O |

| FTP |

O |

O |

O |

| RS-485 |

O |

O |

O |

| DNC(Network) |

O |

O |

O |

| DNC(USB) |

O |

O |

O |

| Information Display |

Operation CV Display |

O |

O |

O |

| Graphic Simulation |

O |

O |

O |

| Partial Graphic Simulation |

O |

O |

O |

| Dynamic Multi-Language Switch |

O |

O |

O |

| Inclined Plane |

Feature Coordinate(Inclined Plane Process G68.2, G68.3) |

Δ |

Δ |

Δ |

| Feature Coordinate Teach |

Δ |

Δ |

Δ |

| 5 axis feature |

5 Axis RTCP (G43.4) |

Δ |

Δ |

Δ |

| Smooth TCP |

Δ |

Δ |

Δ |

| G code command |

High Precision Locus Control Mode (G05P10000) |

Δ |

O |

O |

| Smoothing Path Mode (G05.1) |

O |

O |

O |

| NURBS Interpolation (G06.2) |

Δ |

O |

O |

| Thread Cutting (G33) |

O |

O |

O |

| Auto Tool Measurement (G37) |

O |

O |

O |

| Tool of Offsets (G45~G48) |

O |

O |

O |

| High Speed Peck Drilling Cycle (G73) |

O |

O |

O |

| Left Handed Tapping (G74) |

O |

O |

O |

| High Precision Boring Cycle (G76) |

O |

O |

O |

| Drilling cycling (G81) |

O |

O |

O |

| Chopping (G81.1) |

O |

O |

O |

| Bottom Feed Hold Drilling Cycle (G82) |

O |

O |

O |

| Peck Drilling Cycle (G83) |

O |

O |

O |

| Tapping Cycle (G84) |

O |

O |

O |

| Boring Cycle (G85) |

O |

O |

O |

| High Speed Boring Cycle (G86) |

O |

O |

O |

| Back Boring Cycle (G87) |

O |

O |

O |

| Semi Automatic Finishing Boring Cycle (G88) |

O |

O |

O |

| Bottom Feed Hold Boring Cycle (G89) |

O |

O |

O |

| Multi-Group HSHP Parameter (G120.1) |

O |

O |

O |

| Option |

Option-4 Enable Plugin Function |

O |

O |

O |

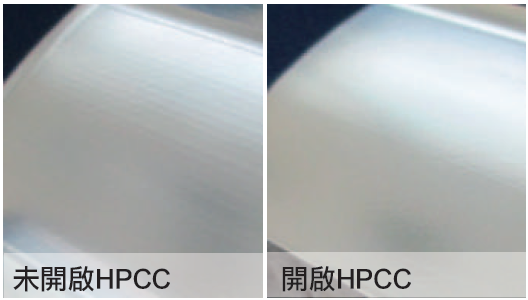

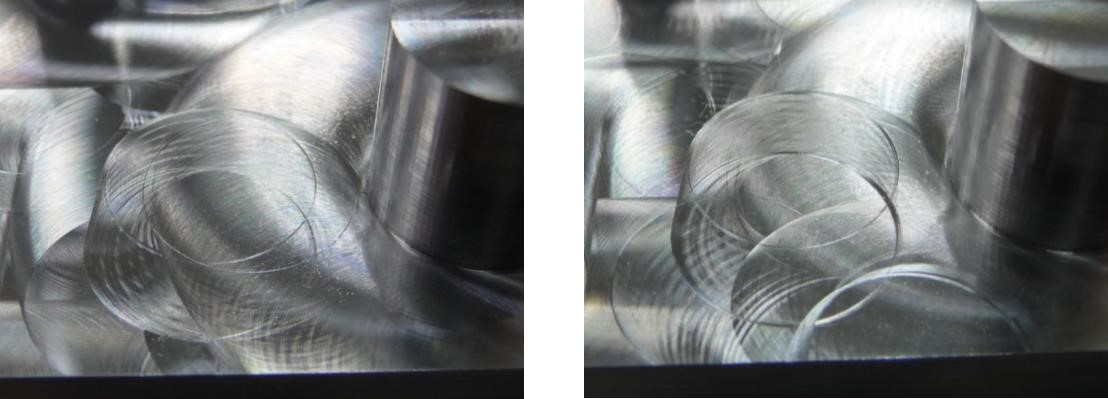

| Option-11 High Precision Contour Control (HPCC) |

Δ |

O |

O |

| Option-12 Rotation Tool Center Point (RTCP) |

Δ |

Δ |

Δ |

| Option-13 Feature Coordinate System |

Δ |

Δ |

Δ |

| Option-14 Parameter learning function |

|

|

|

| Option-15 Tapping Learning |

|

|

|

| Option-16Syntec Vision |

Δ |

Δ |

Δ |

| Option-17 Commercial Vision Software |

Δ |

Δ |

Δ |

| Option-18 CAD/CAM |

Δ |

Δ |

Δ |

| Option-19 3D Arc Interpolation |

Δ |

Δ |

Δ |

| Option-20 Pick and Place (All in one) |

Δ |

Δ |

Δ |

| Option-21 Four Axis Robot |

|

|

|

| Option-22 Five Axis Robot |

|

|

|

| Option-23 Six Axis Robot |

|

|

|

| Option-24 Gantry Robot |

|

|

|

| Option-25 Advanced Look-Ahead |

|

|

|

| Option-26 Smooth Tool Center Point(STCP) |

|

|

|

| Option-27 Multiple mechanisms for five-axis |

|

|

|

| Option-28 The 2nd coordinate supports feature coordinate system |

|

|

|

| Option-29 Four-axis Rotation Tool Center Point Control (4AXRTCP) |

|

|

|

| Option-31 High Speed Chamfering Contour Control |

|

|

|

| Option-32 ROT Servo Turret |

|

|

|

| Option-34 Wood Software |

|

|

|

| Option-35 3D Laser Scanning |

|

|

|

| Option-36 Wood Built-In CAM Function |

|

|

|

Reviews

There are no reviews yet.