-The handheld device integrates dedicated human-computer process that simplifies operation, and is equipped with 7″ touch screen that enables unlimited functional operations, provides the most convenient and user friendly advance handheld controlling system.

-Supports Yaskawa M3 communication.

-Equipped with the Syntec SRI communication port, allows free IO, AD/DA, and PWM module extension

-Support industrial communication protocols: ModbusTCP, EthernetIP, TCP/IP.

-Function customizable industry specific membrane button

-All in one: Control by G-code, M-code, connected to CNC controller directly, decrease the usage of external signal.

-Optional hand wheel provides operation with higher precision

-Works seamlessly with Syntec’s all-in-one drivers that make parameter adjustments fast and easy

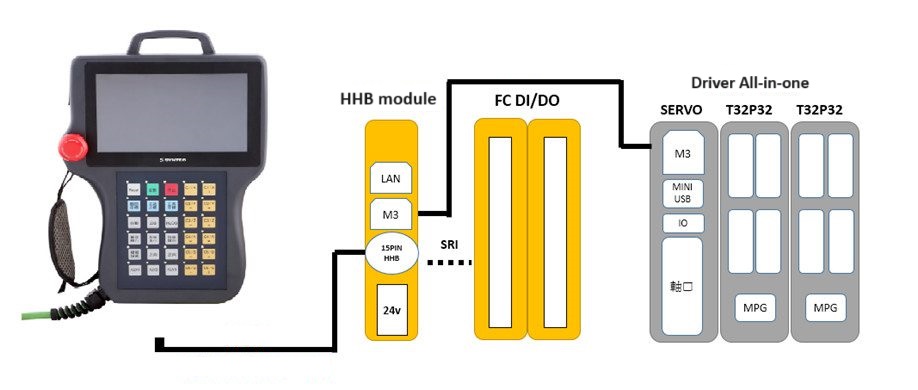

Handheld controller electronic control system architecture

Secondary development preserves difference

-Provide secondary development application tool, can customize PLC, HMI, and MACRO according to user needs

-Support handheld box button customization, user can decide the corresponding functions.

-Provide modulated develop process, easily complies with PLC and HCI for process development completion

High precision movement track with smooth speed programing

-Follows CNC system’s high-speed, high precision quality, supports path insertion and smooth speed programming

-Supports smooth corners to enhance pick-and-place productivity

-Built-in functional algorithm to avoid singularity

-Supoorts multiple model mechanism conversion, no need to self-develop algorithm

Provide handheld for easy teaching

-Dedicated lathe pick-place button names

-Emergency stop button and safety switch

-Optional hand wheel according to needs

Controller highly integrated with vision

-Controller shows vision image, no screen extension needed

-Vision parameters and function settings can be done on the controller

-Easy space coordinate adjustment

-Secondary development can be achieved via G/M codes

Conveyor tracking

-Supports non-stop machining on the conveyor belt, great for food, packaging and flow-line industries

-In coordination with vision measuring, easily achieves high productivity automation manufacturing system

![]()

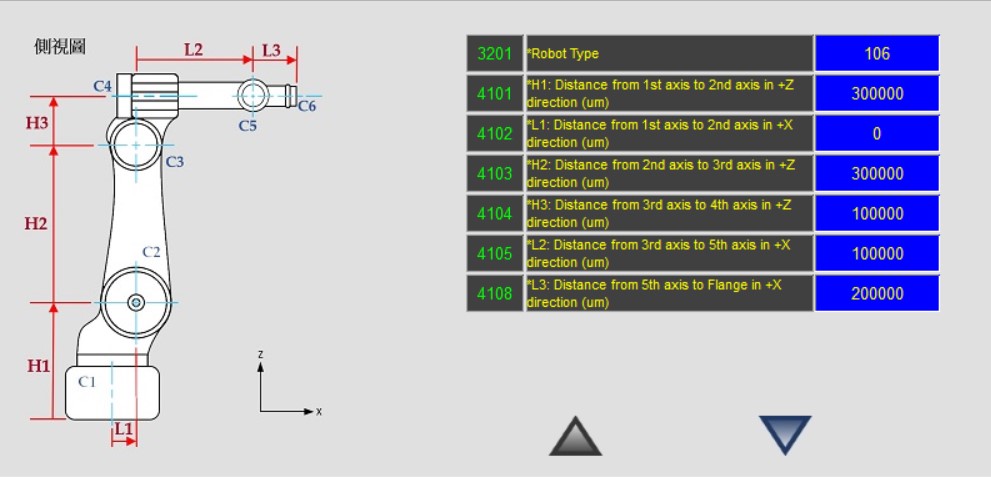

Articulated robot

-Supports syntax input, movement process programed for robotics

-Supports icon instruction for the movement procedure in a dialogue form. Follow the controller’s instructions for parameter input

-Shortens engineer learning curve, without the need to memorize controller process command.

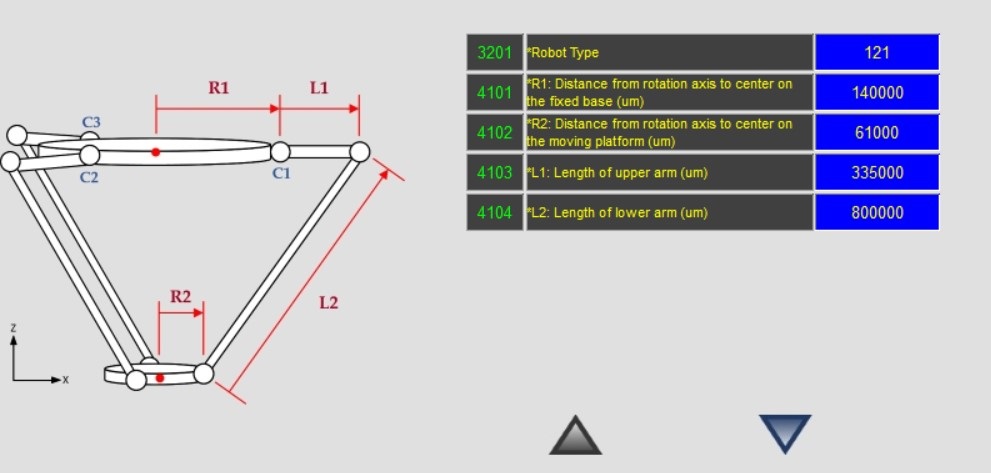

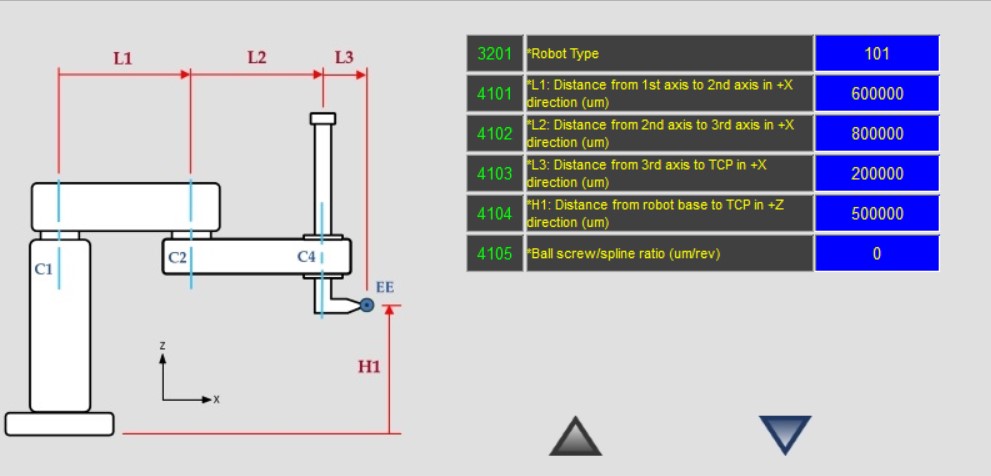

Delta and Scara robot

-Supports syntax input, movement process programed for robotics

-Supports icon instruction for the movement procedure in a dialogue form. Follow the controller’s instructions for parameter input

-Shortens engineer learning curve, without the need to memorize controller process command

-Supports rotating and linear motor models

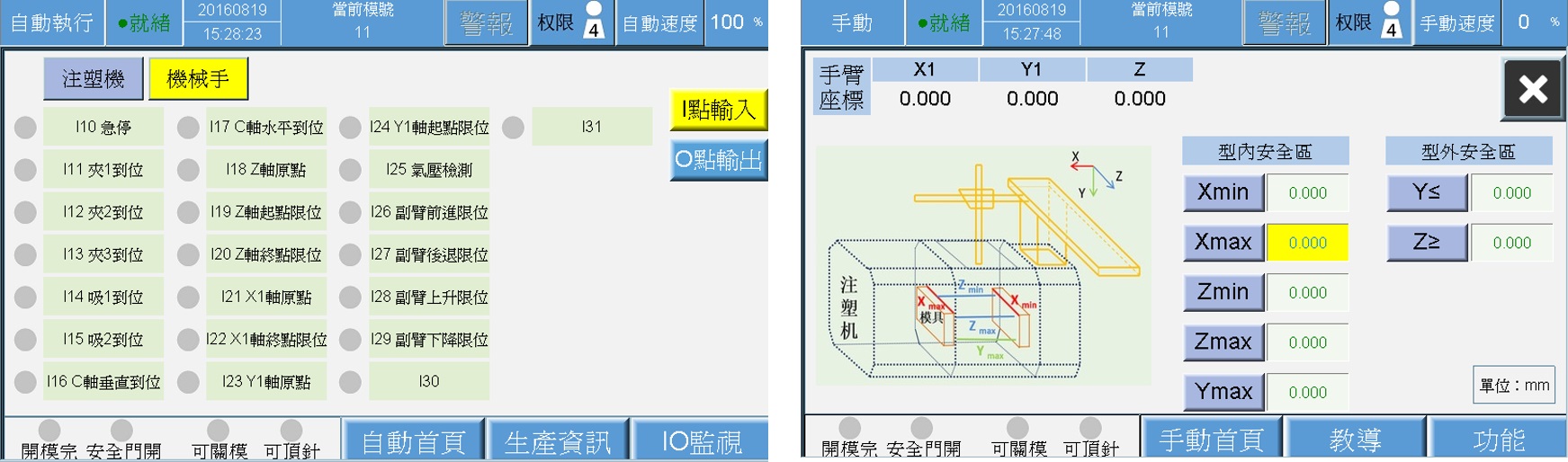

Dedicated Injection molding arm solution

-Built-in reference point teaching, order modular process design

-Developed exclusively for injection molding HCI, I/O ports and monitoring configuration fits accustomed usage

-Provide online process modification, saves teaching time

Dedicated Stamping press arm solution

-Built-in reference point teaching, order combination process design

-Supports straight line at end points, easy for position adjustment and obstacle avoidance

-Supports handheld box and dragging demonstration, providing easier teaching

Dedicated Pick and place robot solution

-Icon instruction for the movement procedure in a dialogue form. Follow the controller’s instructions for parameter input

-Shortens engineer learning curve, without the need to memorize controller process command

-Save multiple sets of pick-place process and reference points, and can be updated according to user needs. Drastically improves ease of use

-Integrates tray control within the controller

-Provide modulated pick-place function

-Support matrix tray, runway tray and customized tray

Reviews

There are no reviews yet.