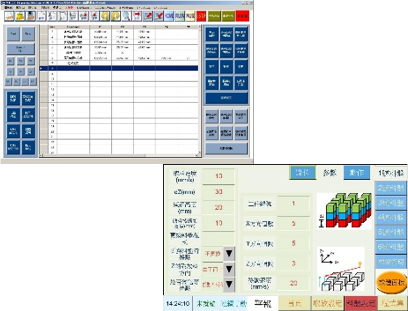

I/O All-in-One Highly Integrated Controller

– Integrate I/O and driver, setting all-in-one.

-There are two versions available, for list and all purpose.

-Fitted size reduces the volume of electrical cabinet.

-With pulse communication axis, it can support variety communicate methods.

-Highly integrated with AD/DA model.

-Equip RS485, VGA, and USB supporting external facilities to in/output.

Highly Integrated and Friendly Customized Development Tool

-Use computer to operate and customize functions easily.

-According to every industry property to develop suitable systems.

-Automation industries are available. Labeling, polishing, bending, mold releasing, and warehouse picking-and-placing are automation types with concrete instance.

-Software and hardware are highly integrated, for example macro program and PLC secondary development.

High External Expandability

-To meet the needs, various external devices are used.

-I/O module

-Touched screen

-Visual localization module

-Cloud monitoring analysis system

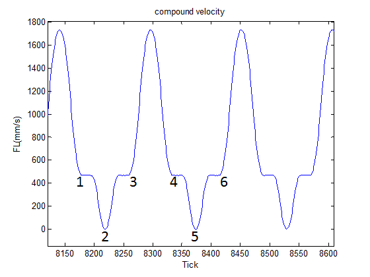

HPCC and SPA

-Followed CNC system with high-speed, high-precision functions, it supports path interpolation and speed smoothing feature.

-Support corners smoothing to increase the efficiency of pick and place.

-Provide not only straight line direction but also circular arc direction.

Reviews

There are no reviews yet.