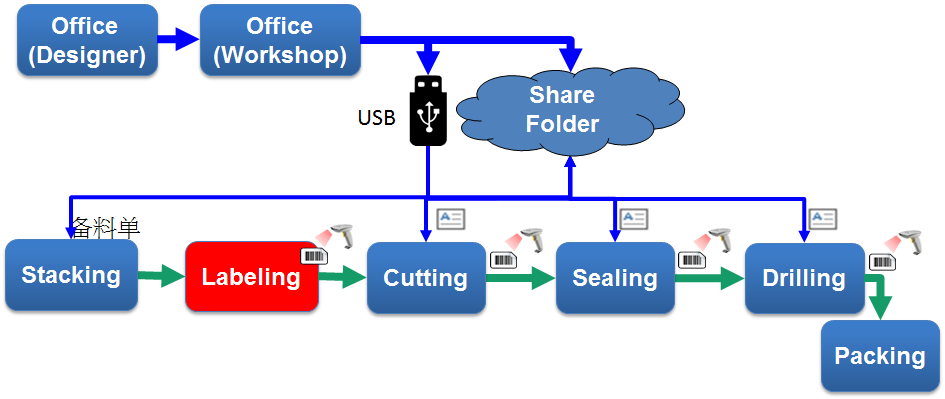

Nowadays raise the demand of intelligent solution to deal with the expansion requirement in customized panel furniture market, the main idea can be shown by the diagram:

Operators design the furniture on CAD software (3D mode), then split into pieces of panels with its dimensional information (2D mode). After that, nest the split panels with identical thickness and properties on corresponding large sheets and generate NC-code files. Operators can transfer NC-code via Internet or U-disk to the controller. The tradition process is classified into 4 main steps:

- Dividing process

- Labeling process

- Edge sealing process

- Boring (Drilling) process

The traditional process is manual labeling after dividing the sheet. However, the information on labels is important to following-up processes. If there is any human error, it might cause the collision of the mechanism on the equipment.

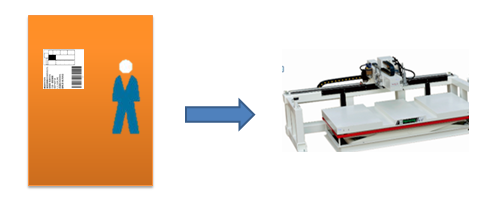

The manufacturing process needs to be optimized and more intelligent so that the productivity can be satisfied, furthermore, the probability of human error can be decreased as well. SYNTEC exhibits Auto Labeling Machine for customized panel furniture market. Labeling sheets before they are cut makes the following production process smoother. Choosing NC code by scanning the Barcodes before sealing edge and drilling ensures the operation is convenient and accurate.

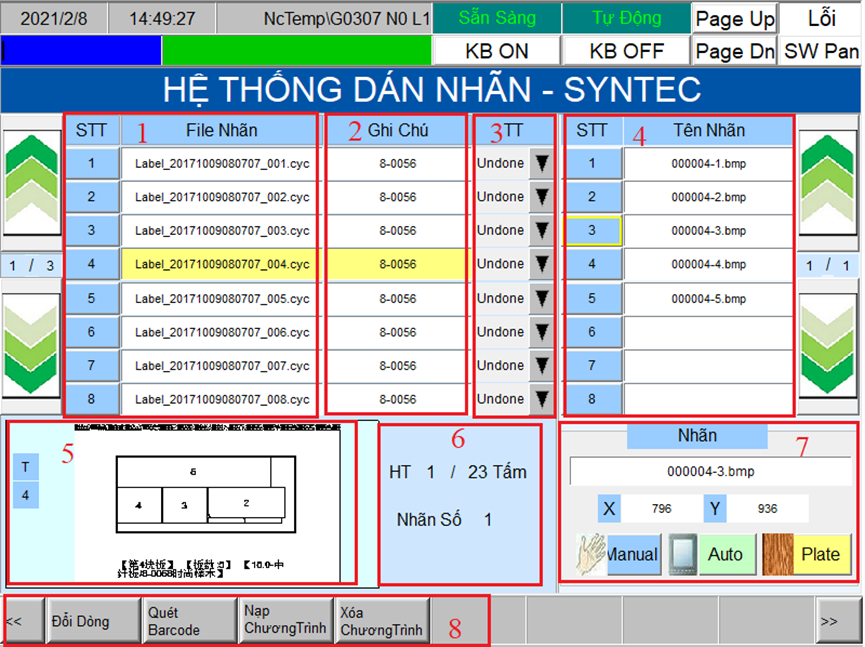

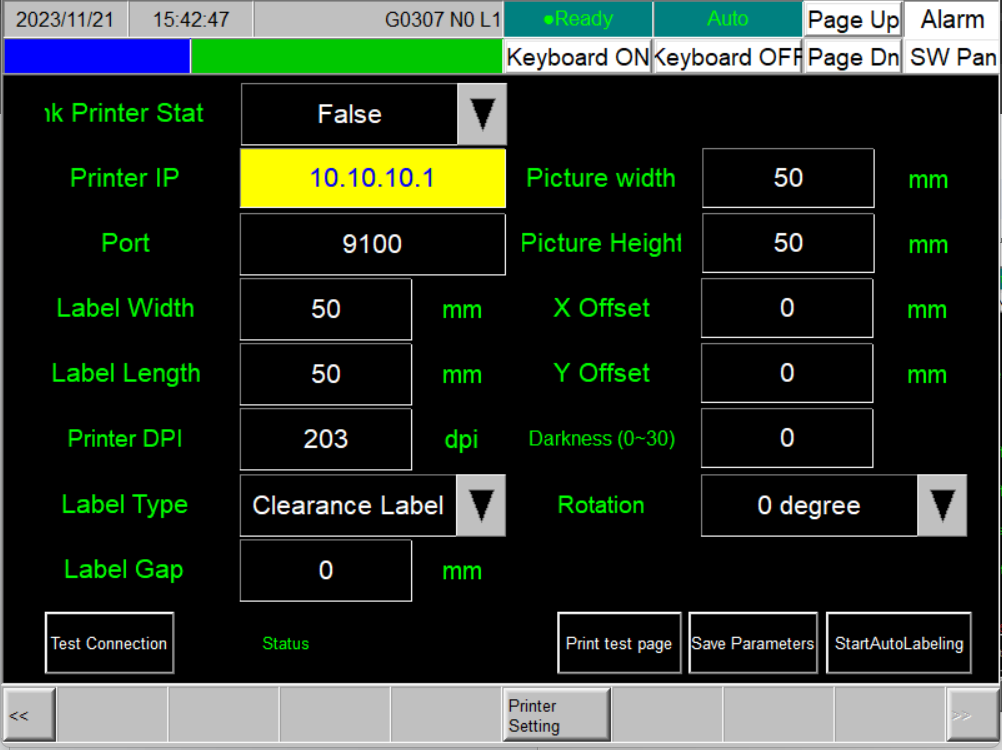

SYNTEC labeling machine controller interfaces

Reviews

There are no reviews yet.