|

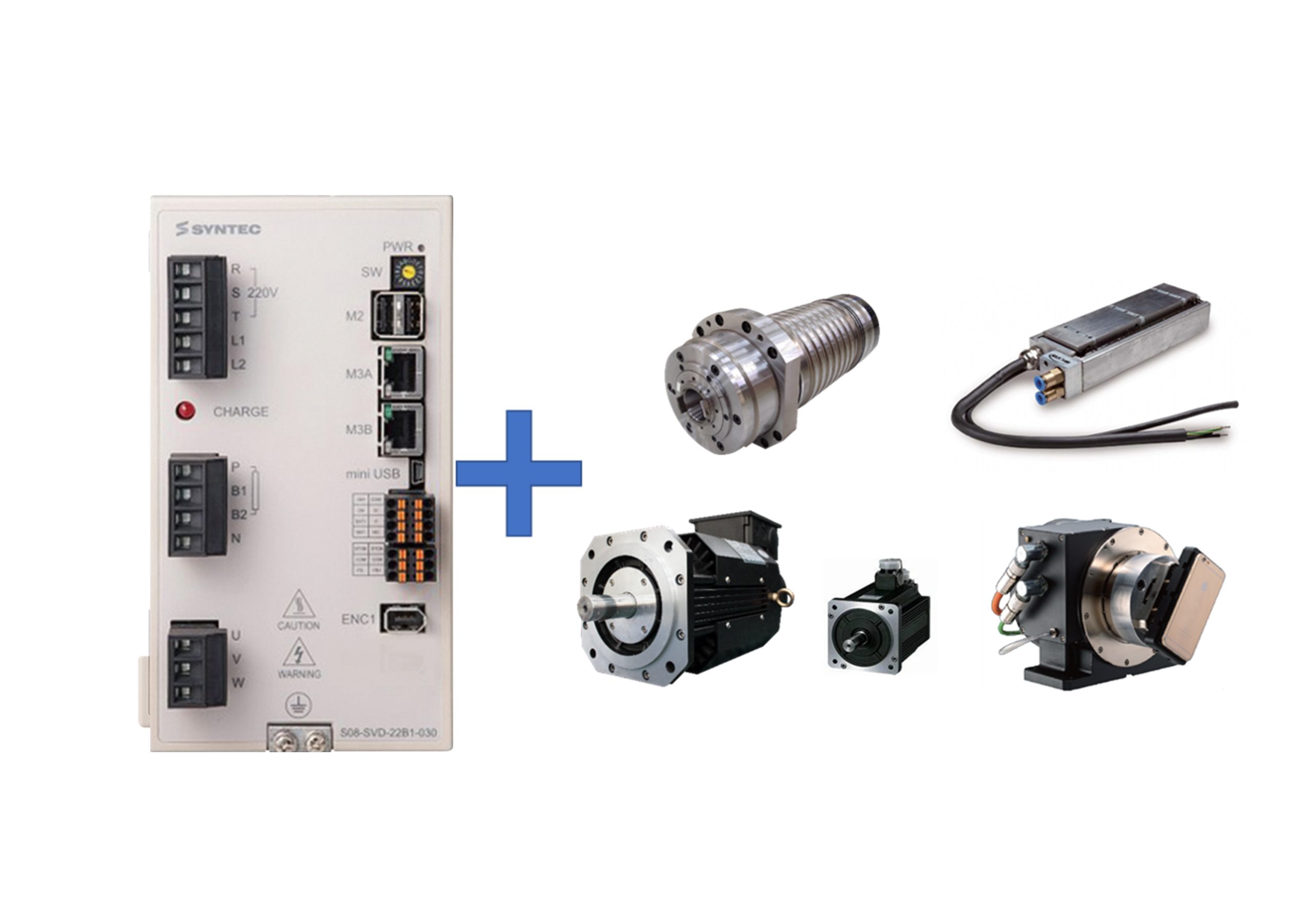

Second generation servo drive series

– Transmission interface upgraded to Mechatrolink III – Servo drive specifications to meet various applications – Matched with spindle servo motors of various specifications – Integrated high-speed host serial communication interface – Supports a variety of servo motor drive functions – New servo adjustment machine Tool Syntec Analytics – Multiple application control functions and simple operation interface |

| Servo drive specifications to meet various applications

-SPD spindle servo series, supports up to 30KW power -SVD axial servo series, supports up to 3KW power -Supports 24-bit analytical absolute encoder communication interface. |

|

|

Equipped with spindle servo motors of various specifications

-Meet the application requirements of various machine tools such as lathes, drilling machines, machining centers and engraving and milling machines -Built-in high-resolution and high-precision encoders to achieve excellent processing performance |

| Integrate high-speed host serial communication interface

-Vertically integrated new generation controller, high-speed serial communication throughout the system -Integrated servo information at the upper level, providing servo parameter monitoring and modification functions -Vertically integrated at the upper and lower levels, providing efficient special functions such as high-speed positioning of the spindle |

|

|

Supports various servo motor drive functions

-Permanent magnet motor and induction motor drive control function -Linear motor drive control function -Fourth axis direct drive motor drive control function |

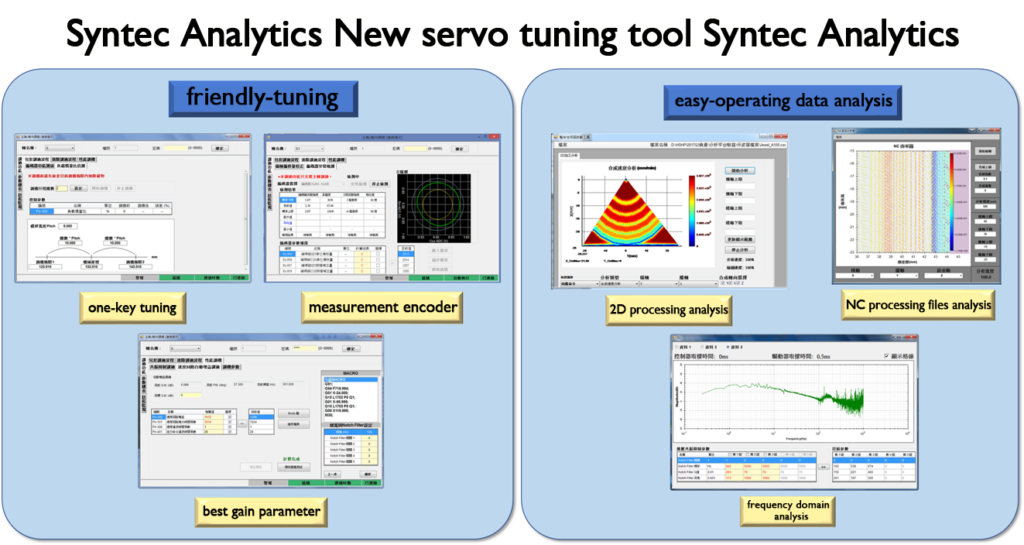

| New servo tuning tool Syntec Analytics

– Adjustment-friendly, including semi-automatic resonance suppression, providing recommended resonance points for suppression – Provides encoder installation testing to ensure accurate feedback and control performance – Provides encoder large wave compensation function for non-sheathed motors using new generation encoders. – Automatic gain adjustment, automatically calculate the best gain parameters by frequency sweep – Simultaneous three-axis processing profile analysis – 2D profile processing analysis, which can simulate the workpiece profile for detailed observation, and provide synthetic speed/acceleration Figures help clarify processing issue |

|

|

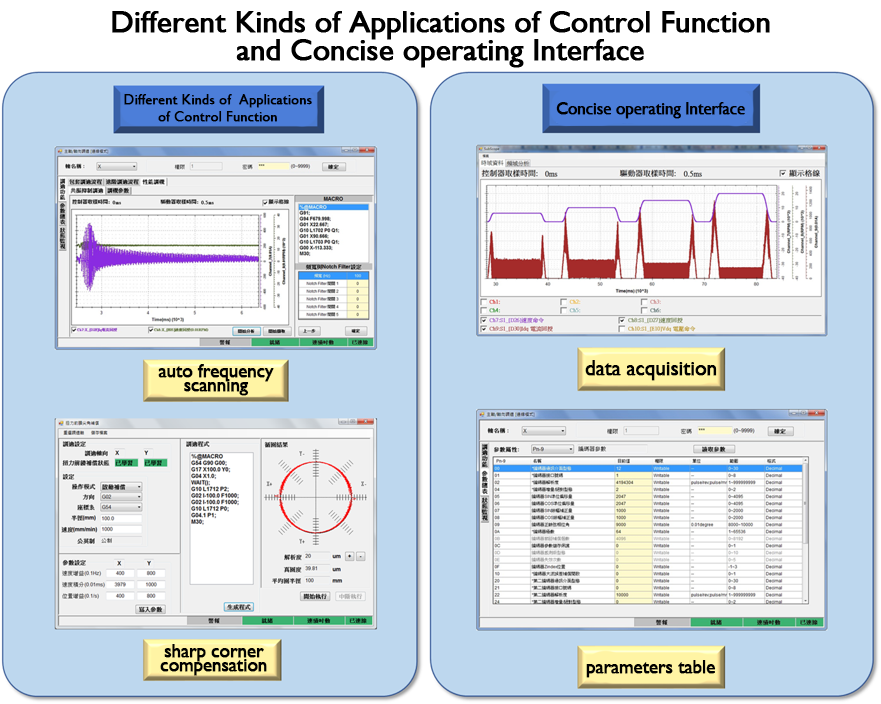

Multiple application control functions and simple operation interface

– Simplify the debugging process, the packaged motor provides one-click adjustment function to improve debugging efficiency – The screen is simple and intuitive, easy to monitor status, measurement and analysis – The parameter setting and data acquisition interface is simple, easy and fast to operate – Data acquisition convenient and conducive to parameter reading, writing or archiving – The oscilloscope can capture controller and driver data at the same time, and provides frequency response and system Bode plot analysis functions |

Reviews

There are no reviews yet.